If you are building "solar panels for your home", one of the most important things to learn is proper soldering of the solar cells. Building your own solar power system can be a very fun project, but if you are having trouble soldering your solar cells then stop right now! When I first started by first attempt to solder, I failed. I thought to my self, "what am I doing wrong", then I discovered the secret to soldering solar cells. Follow the instructions below for perfectly acceptable soldering techniques.

Cells I use - To start this mini-training series, you need to determine what type of solar cells to use. My own personal preference is the 3 x 6 inch cells that are rated at.5 volts each. I found that these are easier to solder and work with.

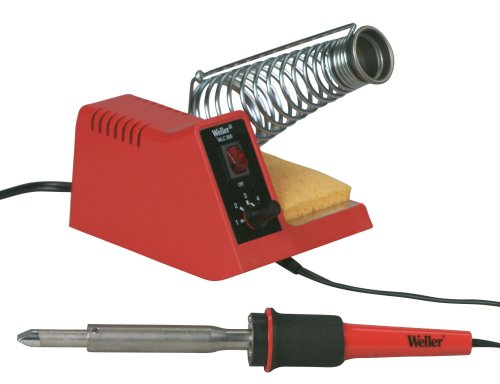

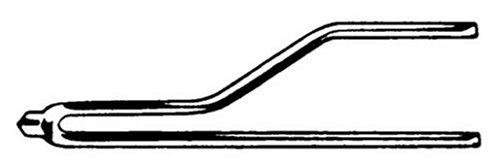

Soldering iron - This is one of the trade secrets of the pros, a proper soldering iron. I have found experimenting with different soldering irons and different wattage of heat the best solutions is to use a 40 watt iron. Buy a good heavy-duty iron, I suggest a soldering station with a wipe sponge to keep your tip clean at all times. The tip I prefer has a slight angle to it and can be easily replaced. To not use any tip wider than 1/8th inch.

Solder to use - This is a very important step in soldering solar cells, the proper solder. There are so many different solders on the market that your head will start to spin wondering which one to use. My rule here, KIS (keep it simple). Any electronics supply will carry solder made for electronics projects that will have a low melting point. This is crucial when soldering our cells.

Soldering flux - It is important that when doing a DIY solar project that you use proper flux. The purpose of soldering flux is to condition the metal that we are attaching to, so that the solder will draw or easily attach. Use liquid flux available in pens designed for electronics.

Heat sink - Here is one of the best steps to follow if you want perfect solder connections. If you want to have consistent soldered connections, then I would recommend using a piece of tempered glass. When I build all my solar cells I use ¼ inch tempered glass. I build all my cells by encapsulating them on the glass, so this works great for soldering them also.

![]()

Soldering Kit

First thing you must do is plug your soldering iron in and let it come to the proper heat temperature. Next, prepare your tip for use by applying solder to it and see if it melts easily. The first time you use your iron you must clean your tip by applying solder then pulling it through your wet sponge, this will coat your tip with a glaze of solder. Now you are ready to get started.

Soldering Kit

I start by making sure my glass is perfectly clean by using some type of glass cleaner. Now take one of your cells face up or the side that faces the sun, this is your negative side when hooking them up. Having already cut your tab wires to the proper length we can start to solder them to the cell.

Apply flux to the two silver strips on the solar cell. Here is a little trick to help make your soldering easier. Use sockets from a socket wrench set to hold down your cell while applying solder; this keeps it in place while preventing warping of the cell. Next, lay your tab wire flat against the silver strip and hold in place using a small flat tip screw driver. Apply a small amount of solder to your soldering iron; this will be all you need since the factory tab wires are already coated with solder. Now draw your soldering tip across the tab wire, you will get the proper feel for this as the solder melts as you move the iron along the solar cell. Keep doing this until you have enough cells to do one complete panel.

After soldering all your negative sides of your cells you are ready to start joining your cells together making your stringers of cells. Turn over one of the recently soldered solar cells then take another one and slide under the tab wires and dab each of the 6 silver solder points with flux, and attach the same way using solder for each of the solder points. Guess what, you have properly soldered your first solar cells!

What is great about this method is that you are already ahead of most people who do not know the proper way to solder solar cells. Just remember, just the right amount and do not leave the heat on to long or you will warp your cell and possibly damaged it.

DIY Solar - Soldering Solar Cells

Soldering Kit

Oct 24, 2011 16:26:39

Click for larger image and other views

>> Click here to update Cheapest prices for Helping Hands with Magnifying Glass <<

>> Click here to update Cheapest prices for Helping Hands with Magnifying Glass <<

Helping Hands with Magnifying Glass Feature

- Great for soldering and working with small items

- 2-1/2" glass lens magnifier

- Heavy cast iron base

- 2 alligator clips mounted on 4 way swivels

Helping Hands with Magnifying Glass Overview

Quality helping hands with solid heavy duty cast iron base, great for soldering and working with small items. Useful tool for electrician, engineers, jewelers and more. Helping hand comes with 2-1/2" glass lens mangifier and 2 alligator clips mounted on 4 way swivels.

SAVE NOW on the special offers below!

Available In Stock. |

| This Helping Hands with Magnifying Glass ships for FREE with Super Saver Shipping. |

|

Limited Offer Today!! Helping Hands with Magnifying Glass Black Friday and Cyber Monday Deals

Twins Strollers